Electric Equipment ROI: How much can you save?

September 08 , 2022

Let’s face it – managing your fleet is a delicate balancing act. Whenever you’re considering adding a new piece of equipment, or replacing an old one, owners need to make sure they’re making the right decision for their bottom line. Because HEVI’s tech is at the forefront of industrial electrification, people sometimes get the impression that it must come with a hefty price tag. But the truth may surprise you – and we’re here to break down the electric equipment ROI* you’ll see when you replace an old diesel dinosaur.

Cost of the Equipment

One of the very first considerations is how much your new equipment will cost as soon as you sign on the dotted line. Although it’s new tech, our strong manufacturing capabilities and direct sales model means we can easily compete with ICE equipment pricing. That’s why it’s part of HEVI’s mission to achieve price parity with its competitors, so your new piece of HEVI equipment will cost the same as a comparable diesel model. When calculating ROI, it’s not even necessary to include purchase price – HEVI equipment won’t cost you more than what you’re used to, and it will save you money on fleet management.

CAT 906M Diesel Wheel Loader: $132,000

HEVI GEL-1800 Electric Wheel Loader: $135,000

Maintenance of the Equipment

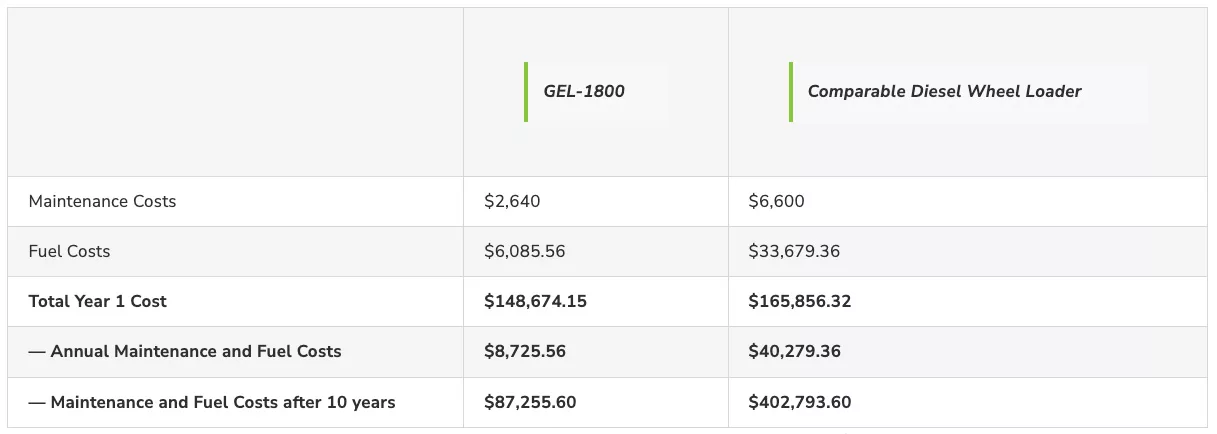

Of course, fleet management is more than just buying new and scrapping the old. All of your machines need to be maintained or even repaired, and that costs money. It’s well established that electric motors require less maintenance that internal combustion engines – primarily due to the decrease in moving parts. As a result, you can be sure that HEVI’s equipment will suffer fewer mishaps and breakdowns over its lifetime compared to your previous diesel model. The US Office of Renewable Energy has shown that EVs save approximately 40% on maintenance every year.

Potential Diesel Maintenance Costs: $6,600 annually

Potential Electric Maintenance Costs: $2,640 annually

Fuel Consumption

Finally, power needs fuel, and whether diesel or electric, you will have to pay to power your industrial heavy equipment. In terms of electric equipment ROI, diesel is more expensive. With diesel at $5.06 per gallon and industrial electricity at 7.26 cents per kilowatt hour (as of 10/2022), diesel is a real drain on the wallet.

Diesel Fuel Costs (3.2 gal/hour for 2080 hours of operation): $33,679.36 annually

Electricity Costs (141 kWh battery for 2080 hours of operation): $6,331.18 annually

It All Adds Up: Electric Equipment ROI is Superior

After purchase, and without account for depreciation or rising fuel costs, a diesel wheel loader would cost $470,563.2 over the span of its lifetime. Our GEL-1800, however, would cost nearly half that amount at $219,255.60.

You would save $251,307.60 if you chose to purchase the GEL-1800 over the Caterpillar 906M. So, should you pay nearly half a million dollars over the next 10 years with a diesel machine stinking up your jobsite, or should you save a quarter of a million dollars?

We’ll let those numbers speak for themselves.