Comparing Electric vs. Diesel: Does Electric Heavy Equipment Have Enough Power?

August 11 , 2022

When Tesla was first launching its vehicles, it needed to speak to its potential customers in a language they could understand. American consumers were used to thinking of their cars in terms of horsepower, but electric motors are rated in terms of torque and kWh. It would be hard to sell cars based on torque and kWh when consumers already understood, “My engine gets 190 horsepower.”

So Tesla did some math. By converting torque and kWh into horsepower, they could finally deliver a comparison between their new electric product and the old standard.

At HEVI, we get a lot of people asking whether or not our electric equipment is “as powerful” as traditional diesel equipment. Unfortunately, we believe that straight horsepower comparisons between electric motors and internal combustion engines are a little misleading – electric motors end up rating with huge amounts of horsepower, despite not being able to apply that power in the same way as an internal combustion engine. Case in point, the Tesla Model S Plaid is listed as having 1,020 horsepower – around 5 times more than traditional vehicles. So how is it that the 216mph speed record for that model was only recently hit? In contrast, the 647HP Ford GT was released in 2017 with a top speed of 216mph. With less than 2/3rds the horsepower, the Ford GT was reaching the same speeds 5 years earlier.

The answer lies in acceleration – the Model S Plaid will hit 60mph in just 2.1 seconds, while the Ford GT will take 3.2 seconds to reach the same speed. Plainly said, HEVI feels this distinction isn’t widely known, and therefore, trying to review electric vs. diesel in terms of horsepower can be a bit misleading.

Electric vs. Diesel: Stats To Know

When you’re looking to determine whether electric equipment can keep up with your existing diesel-based fleet, you’ll need to check out four different stats, which you can remember with the acronym HOLO:

- Hydraulic Pressure

- Operating Weight

- Load Rating

- Operational Time

Hydraulic Pressure

A big question we often get is, “Will HEVI equipment be as powerful as my current diesel equipment?” As we mentioned before, it’s hard to make a direct 1:1 comparison between electric and diesel, but this question is what drove us to create this article. The truth is, there is a huge misunderstanding when it comes to most heavy industrial equipment.

Your engine does not determine your power, your hydraulics do. In fact, an engine is just a power source for increasing the hydraulic pressure – burning diesel does not provide any performance benefits to the hydraulic system. In fact, that’s one reason massive hydraulic presses tend to be all-electric – without the need to move the press around, a diesel engine doesn’t make any sense because an electric motor can provide all the power needed.

So, when you want to know if a piece of equipment has the sheer force to be able to handle your jobs, you’ll want to compare the numbers for the maximum hydraulic working pressure. Returning to the 906M, we can see a maximum working pressure of 3408 psi. The GEL-1800 has a maximum working pressure of 3625 psi. Because we use hydraulic systems comparable to other machines you’re familiar with, you can rest assured that you’ll get the same raw power from HEVI equipment as with your diesel machines.

Operating Weight

Operating weight has been a long-time industry standard for understanding what your equipment can do. The heavier it is, the more it can dig, the more it can lift, and the better it can push – while not a perfect comparison, operating weight does provide a good ballpark sense of what a given piece of equipment can do.

When comparing electric vs. diesel equipment, operating weight is still a great place to start. Generally speaking, the operating weight of a HEVI loader will allow you to identify similar diesel-based models that you may already be familiar with. For example, with only a half-ton difference in operating weights, the CAT 906M and the GEL-1800 are comparable models.

Load Rating

Of course, one of the best ways to get to the heart of the question for many vehicles (loaders, excavators, etc.) is through the load rating. Usually, manufacturers provide several different load statistics, from static tipping load ratings to full turn tipping load ratings and more. By looking at these stats, you can identify what loads are too big for your equipment.

When comparing electric vs. diesel equipment, the load rating is the purest comparison you can get. A machine can only lift according to its rating, and so if you know you’ll have 1 ton to move, you pick a piece of equipment that can lift 1 ton. Looking again at the CAT 906M, we see a tipping load of 8666 lbs, while the GEL-1800 has an 8,378 lb load capacity. Industry-standard suggests that operating capacity is roughly 50% of the tipping load, so these pieces of equipment should be able to lift 4333 lbs and 4189 lbs respectively. For your convenience, we name all of HEVI’s equipment with the rated load in mind. The GEL-1800 is rated for 1.8 metric tons – this way you can make a quick and easy decision when considering buying a new loader.

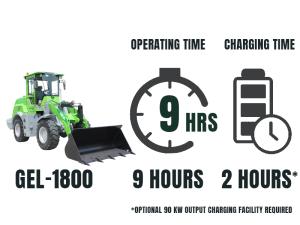

Operational Time

Finally, the last way to make sure you’re getting the right equipment for the job is to look at operational time. For traditional diesel equipment, this is admittedly less of a concern – no one worries about what happens when they run out of fuel. When you get low on diesel, you refuel and you’re back to work.

Electric equipment, however, cannot fully “refuel” as quickly as diesel machines. A full charge is recommended and will often take longer. This is why it’s important to look for the Operational Time rating on your electric vehicle. For HEVI’s electric equipment, we guarantee a full-shift of uptime from a full charge. Considering that the 906M, with a 13.7-gallon fuel tank, would have to refuel at least once during a work day, our GEL-1800 can outlast the competition for your entire shift.

Honorable Mention: Maintenance Downtime

As one final consideration, you can look to maintenance time as another reference point when thinking about upgrading your fleet to electric. Although not a specific stat you’ll find listed, internal combustion engines are more costly to maintain than electric motors. Electric motors have far fewer maintenance requirements as there are fewer moving parts, so the average cost of keeping your vehicle running will be much lower. Furthermore, because it will break down less often, the overall downtime time of HEVI equipment is also considerably less!

Electric vs. Diesel: When the Environment Wins, We All Win

In conclusion, though a lot of manufacturers want you to make a straight apples-to-apples comparison with existing diesel- or gas-powered equipment, the truth is that electric equipment is really in a class all its own. When you are considering upgrading to electric equipment, it will be critical to remember to look for the HOLO stats – Hydraulic Pressure, Operating Weight, Load Rating, and Operational time. When you know what you’re looking for, you can make the smartest purchasing decision possible.

To take a look at how some of our other equipment compares, visit gethevi.com/equipment